Applying:

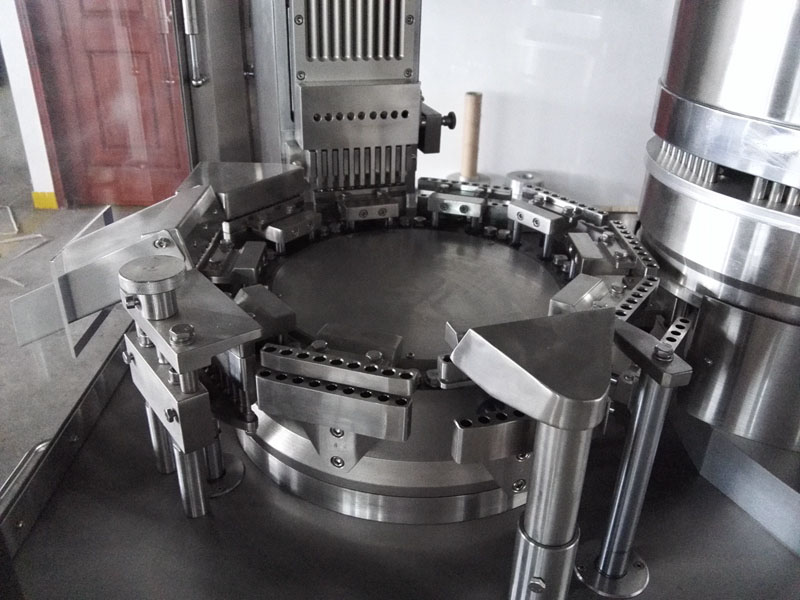

This machine is used for filling the powder or pellet into the capsule automatic,it is widely used in Pharma field.

Futures:

1) Nice appearance, exquisite workmanship, ease operation.

2) Stowage seat and measuring plate are designed as one unit to make measuring plate and stowage rod without deviation phenomenon, avoid friction phenomenon between stowage rod and measuring plate, improve its precision highly, expand the machine's life .

3) Ineligible capsule can be eliminated automatically(qualified rate not included), the medicine in the capsule can be recycled and be reused, increase greatly economic benefit.

4) Easy dismantling , installation and clean, different mould can be replaced manually on the same machine

5) Dust collector and vacuum pipe as well as waste air pipe are installed in the inner of the machine , avoid the air pipe becoming hard, broken and leakage , it is more convenient to clean the operating platform. The medicine can not contact with organic material meet the GMP the requirement

6) The cap of stowage rod is made of stainless steel to replace original plastic cap to void breaking phenomenon; decrease the screws and caps on the platform

7) Adopt the PLC,touch screen,the touch screen can set the password.Automatically set the parameter.printing data,etc function

8) Can automatically alarm,automatically stop when the machine encounter a breakdown or lack material,the wearing parts are all imported

Parameters:

| Model: | NJP-1200 |

| Capacity: | 1200capsules/minute |

| Machine suitable for: | capsule Size #00 to 5 |

| Power supply: | 220v/380v 50Hz three phase (it can be changed depend on your requirement) |

| Power consume: | 3kw |

| Quantity of mould bores: | 9pcs |

| Noise standard: | ﹤75dB(A) |

| Weight: | 1100kgs |

| Overall dimension: | 970×870×1900mm |

We can offer you different capacity capsule filling machine Max capacity 7500pcs/min